Manual inventory management leads to costly errors, lost time, and missed sales opportunities. As businesses grow, keeping track of stock using spreadsheets or paper quickly becomes overwhelming and prone to mistakes. To address these challenges, it’s crucial to automate inventory management. Automating this process streamlines operations, reduces manual input, and provides businesses with real-time visibility over their entire inventory. This guide delivers a step-by-step playbook so you can confidently transition from manual processes to automated systems—unlocking efficiency, accuracy, and data-powered growth.

What Is Automated Inventory Management?

Automated inventory management uses technology—software, sensors, barcodes, and integrated systems—to track, manage, and control inventory with minimal manual intervention. Unlike manual inventory processes, automation reduces errors and delivers up-to-date data for better decision-making.

Key Principles of Automated Inventory Management:

- Automated tracking of stock movements (receiving, selling, returns)

- Integration with sales channels and business tools (e.g., Shopify, Quickbooks)

- Technology use: cloud-based inventory management systems, barcodes, RFID, IoT devices

Technologies Involved:

- Barcodes & RFID: Enable fast, error-free item tracking with handheld scanners or automated readers.

- Inventory Management Software: Centralizes stock records, automates reordering, and generates real-time reports.

- IoT Devices: Sensors and smart shelves give deeper, instant insights into inventory levels, locations, and conditions.

| Manual Inventory Management | Automated Inventory Management |

| Paper logs or spreadsheets | Cloud-based or on-premises software |

| Physical counts, error-prone | Scanning, sensors, real-time updates |

| Time-consuming data entry | Automatic data capture and sync |

| Lack of real-time visibility | Live stock levels across all locations |

| Higher risk of errors/stockouts | Automated alerts, better accuracy |

What Are the Benefits of Automating Inventory Processes?

Automating inventory processes lowers labor costs, cuts errors, and gives businesses the agility to meet demand quickly. The shift to automation provides:

- Fewer Human Errors: Automated systems eliminate most manual data entry mistakes, reducing discrepancies and write-offs.

- Real-Time Tracking: Instantly know inventory levels across warehouses and sales channels.

- Speed and Efficiency: Faster stock reconciliations and automated reordering save time.

- Cost Savings: Prevent lost sales from stockouts and reduce excess inventory through accurate demand forecasting.

- Scalability: Support for multi-location businesses with consistent, centralized oversight.

Quick Win Table: Manual vs. Automated Inventory Impact

| Factor | Manual | Automated |

| Error Rate | High | Low |

| Inventory Visibility | Delayed | Real-time |

| Stockouts | Common | Rare |

| Labor Hours | Intensive | Minimal |

| Response Speed | Slow | Fast |

According to a 2023 Statista report, businesses adopting inventory automation typically see inventory error reductions of up to 70% and save 25–30% on operational labor costs.

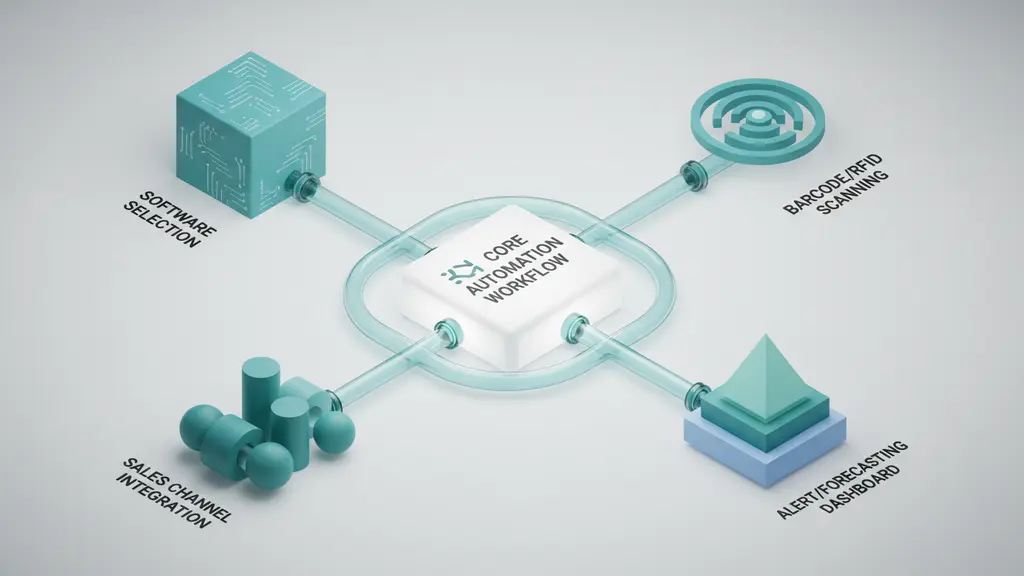

How Does Automated Inventory Management Work?

Automated inventory management operates through a defined workflow: from choosing the right tools to integrating them into daily processes for seamless, error-free operations.

Typical Automation Workflow:

- Select suitable inventory management software or system.

- Integrate sales channels (POS, ecommerce, accounting).

- Set up data capture (barcodes, RFID, or IoT sensors).

- Configure automation layers (reorder thresholds, alerts, forecasting).

- Train staff and test end-to-end processes.

- Monitor performance, optimize and scale as needed.

Core Automation Elements:

- Data Capture: Scanning items in/out with barcodes or sensors.

- Synchronization: Updating stock levels across all channels in real time.

- Automated Alerts: Notifying users of low stock, anomalies, or reordering needs.

Visual Flowchart: An infographic is recommended here—mapping purchase orders through receipt, automated tracking, reorder triggers, and reporting dashboards.

Step-by-Step Guide: How to Automate Your Inventory Management

Implement automated inventory management through these distinct steps to ensure a smooth and successful transition:

- Evaluate Readiness

- Assess current processes: Are you frequently dealing with stockouts, excess stock, or data discrepancies?

- Confirm stakeholder buy-in and allocate a project lead for the transition.

- Select the Right System (ERP, IMS, WMS)

- Prioritize needs: scalability, ease of use, integrations, support, cost.

- Compare leading vendors based on your business size and industry.

- Integrate with Sales Channels and Business Tools

- Connect software to ecommerce (Shopify, WooCommerce), POS, and accounting systems (Quickbooks, Xero) for full data sync.

- Set Up Data Capture: Barcodes, RFID, IoT Devices

- Choose hardware based on business scale. Barcodes suit most; RFID adds automation but is costlier.

- Barcode/RFID vs. No-Barcode: Small businesses may start with digital logs or app-based scanning.

- For low-tech needs, consider Bluetooth-enabled scales or manual batch updates.

- Configure Automated Reorder Points, Inventory Thresholds, and Alerts

- Set minimum stock levels and automatic notifications for timely reordering.

- Use demand forecasting tools (many included in modern IMS) for proactive planning.

- Enable Analytics, Forecasting, and Reporting

- Use dashboards for real-time insights: stock turns, shrinkage, sales trends.

- Generate scheduled reports for inventory audits and compliance.

- Train Staff and Manage Change

- Provide hands-on training and accessible usage guides.

- Encourage feedback to ease adoption and resolve workflow gaps.

- Pilot, Test, and Optimize Before Full Rollout

- Launch in a limited environment or one warehouse first.

- Test data accuracy, integrations, and process handoffs.

- Adjust workflows, resolve issues, and monitor KPIs before scaling up.

What Are the Key Features to Look for in Inventory Automation Software?

Selecting the right inventory automation software is crucial—focus on features that drive time and cost savings, data accuracy, and integration flexibility.

Essential Features Checklist:

- Real-time inventory tracking (including multi-location support)

- Automated low-stock alerts and smart reordering

- Demand forecasting and analytics dashboards

- Seamless integrations (Shopify, POS, accounting/ERP)

- Mobile device access and user role permissions

- Cloud-based storage and data backup

- Open APIs for future custom integrations

| Feature | NetSuite | Katana | Brightpearl | Cin7 |

| Real-time tracking | ✅ | ✅ | ✅ | ✅ |

| Multi-location support | ✅ | ✅ | ✅ | ✅ |

| Reorder automation | ✅ | ✅ | ✅ | ✅ |

| Accounting integration | ✅ | ✅ | ✅ | ✅ |

| Mobile access | ✅ | ✅ | ✅ | ✅ |

| Forecasting/analytics | ✅ | ✅ | ✅ | ✅ |

| Retail POS link | ✅ | ✅ | ✅ | ✅ |

Do You Need Barcodes or RFID to Automate Inventory?

Barcodes and RFID are common in inventory automation but not strictly required—especially for small businesses or those just starting out. Automation can succeed with digital forms, mobile apps, or simple stock count tools, though the efficiency gains may be slower.

Pros of Barcodes/RFID:

- High accuracy and speed for capturing movements and audits

- Ideal for companies with many SKUs or multiple storage locations

Cons/Alternatives:

- Initial setup cost for hardware and printing

- For low-volume or single-location operations, spreadsheet-driven apps or simple scanning accessories may suffice

- Small businesses often automate by combining cloud inventory software with manual entry or Bluetooth-enabled scanning apps

| Solution | Cost | Best For | Speed/Accuracy |

| Barcodes | Low/medium | Most SMBs, retail | High |

| RFID | High | Large/complex ops | Highest |

| No-barcode (app) | Low | Small/simple SKUs | Moderate |

Example:

A boutique retailer cited on Reddit reported streamlining inventory by using Katana’s mobile app and basic barcode scanners, enabling same-day reconciliation without a complex RFID setup.

Sector-Specific Strategies: How Different Industries Automate Inventory Management

Different industries use tailored inventory automation strategies to address unique challenges.

Retail:

Need for multichannel stock sync, fast-moving SKUs, and POS integration

Automated reordering to avoid out-of-stocks across brick & mortar and online

Manufacturing:

Batch/lot tracking, raw materials management, and compliance with safety standards

Integration with production schedules and supply chain partners

Ecommerce:

Supports multi-warehouse logistics, channel integration, and auto-updating for 24/7 sales

Key benefit: accurate reporting to prevent overselling

Healthcare & Food:

Regulatory compliance (tracking expiry dates, recalls)

Detailed control of medical/food stock and environmental conditions (temperature, etc.)

| Industry | Key Pain Point | Automation Solution | Example Outcome |

| Retail | Stockouts, shrinkage | Channel integrations, POS sync | 40% reduction in lost sales (Brightpearl research) |

| Manufacturing | Batch compliance | Batch tracking, supplier integration | Improved audit readiness |

| Ecommerce | Channel overload | Multi-warehouse, API sync | Accurate stock across Amazon, Shopify, WooCommerce |

| Healthcare | Regulation, safety | Expiry date management, tracking via RFID | Faster recalls, reduced waste |

Implementation Pitfalls and How to Avoid Them

Automating inventory can be transformative or disruptive—depending on execution. Avoiding common mistakes is crucial for success.

Common Pitfalls:

- Skipping a thorough needs assessment or stakeholder engagement

- Poor integration planning with existing tools or data sources

- Inadequate staff training and change management

- Overlooking post-go-live monitoring and optimization

Troubleshooting Tips:

- Start with a limited pilot to identify issues before wide rollout.

- Prioritize integration; mismatched data between sales, finance, and inventory is a leading cause of failed projects.

- Regularly audit data accuracy and user adoption metrics.

| Mistake | Prevention |

| Incomplete integration | Map all data flows before setup |

| Little/no staff buy-in | Involve users in system selection |

| Ignoring analytics | Schedule post-implementation reviews |

| Training gaps | Run onboarding and provide resources |

What’s Next? Trends Shaping the Future of Automated Inventory Management

Emerging technologies are redefining what’s possible with inventory automation, offering more predictive, precise, and scalable solutions.

- AI-driven Forecasting: Uses historical and real-time sales data to predict inventory needs and automate purchasing decisions.

- IoT Sensors: Enable granular, item-level live tracking and environmental monitoring (e.g., temperature-sensitive goods).

- Robotics & Smart Warehousing: Automated guided vehicles (AGVs) and robotics optimize warehouse operations and picking.

- Regulatory Shifts: Data privacy, track-and-trace, and industry-specific compliance are shaping system requirements.

According to industry sources (Statista, ASCM), the global market for warehouse robotics and AI-driven inventory tools is projected to double by 2027, signaling a significant shift toward intelligent inventory automation.

Inventory Automation Toolkit: Vendor Selection Checklist & Resources

Use this checklist to evaluate, select, and successfully implement inventory automation:

Readiness & Fit Questions:

- Are your manual processes causing significant errors or delays?

- Do you sell across multiple channels or locations?

- Is integration with existing software required?

- What level of user support and training is needed?

Technical & Feature Evaluation:

- Does the tool support real-time, multi-location tracking?

- Are automated reordering and forecasting accessible?

- Are integrations available for your POS, ecommerce, and accounting tools?

- Is mobile/device access supported?

- What data backup and security features exist?

FAQs: Automated Inventory Management

What is automated inventory management?

Automated inventory management uses software and technology (like barcodes, RFID, IoT) to track and control inventory levels, movements, and orders, minimizing manual work and errors.

How does an automated inventory management system work?

These systems automatically capture stock data (via scanning or sensors), update inventory records in real time, trigger reorder alerts, and generate reports, often integrating with sales and accounting tools.

What are the key features of inventory automation software?

Essential features include real-time tracking, automated reordering, multi-location support, analytics/dashboards, mobile access, integration with ecommerce/POS systems, and user permissions.

Do I need barcodes or RFID to automate inventory?

Barcodes and RFID are helpful but not mandatory. Small businesses can use manual entry, mobile device scanning, or software apps as a starting point before investing in hardware.

Can small businesses afford inventory automation?

Yes. Many cloud-based inventory management solutions are scalable and priced for small businesses, with entry packages offering core automation features and integration options.

What are the main benefits of automating inventory processes?

Benefits include reduced errors, lower labor costs, faster stock reconciliation, fewer stockouts, real-time visibility, and improved scalability across locations or channels.

How do you choose the right inventory automation tool?

Assess your inventory volume, channels, and integration needs. Compare features, vendor reliability, customer support, and user reviews to select a fit-for-purpose system.

What pitfalls should I avoid when automating inventory management?

Avoid poor planning, insufficient integration, lack of staff training, and skipping regular audits after implementation.

What sectors benefit most from automated inventory?

Retail, manufacturing, ecommerce, healthcare, and food sectors gain significant value from automation due to their complexity and compliance needs.

How is inventory automation evolving with AI and IoT?

AI and IoT enable predictive analytics, real-time environmental monitoring, and autonomous warehousing—leading to smarter, more adaptive inventory strategies.

Conclusion

Automating inventory management transforms time-consuming, error-prone processes into efficient, data-driven workflows. With the right step-by-step approach, business leaders achieve real-time visibility, prevent costly errors, and set the stage for scalable growth. To get started, assess your needs, compare top tools, and use the vendor checklist above.

Key Takeaways

- Automating inventory reduces manual errors, saves time, and provides real-time insights.

- The transition requires careful planning, the right technology, and staff training.

- Barcodes and RFID are helpful but not essential for every business; scalable solutions exist for all sizes.

- Industry-specific automation strategies address unique challenges in retail, manufacturing, ecommerce, and healthcare.

- Future trends such as AI and IoT are making inventory automation smarter and more predictive.

This page was last edited on 29 January 2026, at 12:25 pm

Contact Us Now

Contact Us Now

Start a conversation with our team to solve complex challenges and move forward with confidence.